1. Client Inquiry & Initial Consultation

2. Define Project Scope & Requirements

- Establish Design Requirements: Define functional needs, dimensions, materials, colors, and durability.

- Identify Project Constraints: Clarify limitations on size, cost, and complexity based on client needs.

- Provide Quote & Timeline: Present a proposal with estimated costs, timeline, and terms for approval.

3. Concept Design & Initial Modeling

- Sketch Initial Concepts: If required, create rough sketches or digital illustrations to establish the basic design.

- Develop 3D Model: Using CAD software, create a digital 3D model of the object based on client specifications.

- Client Review & Feedback: Present the 3D model for client review, gather feedback, and make any necessary adjustments.

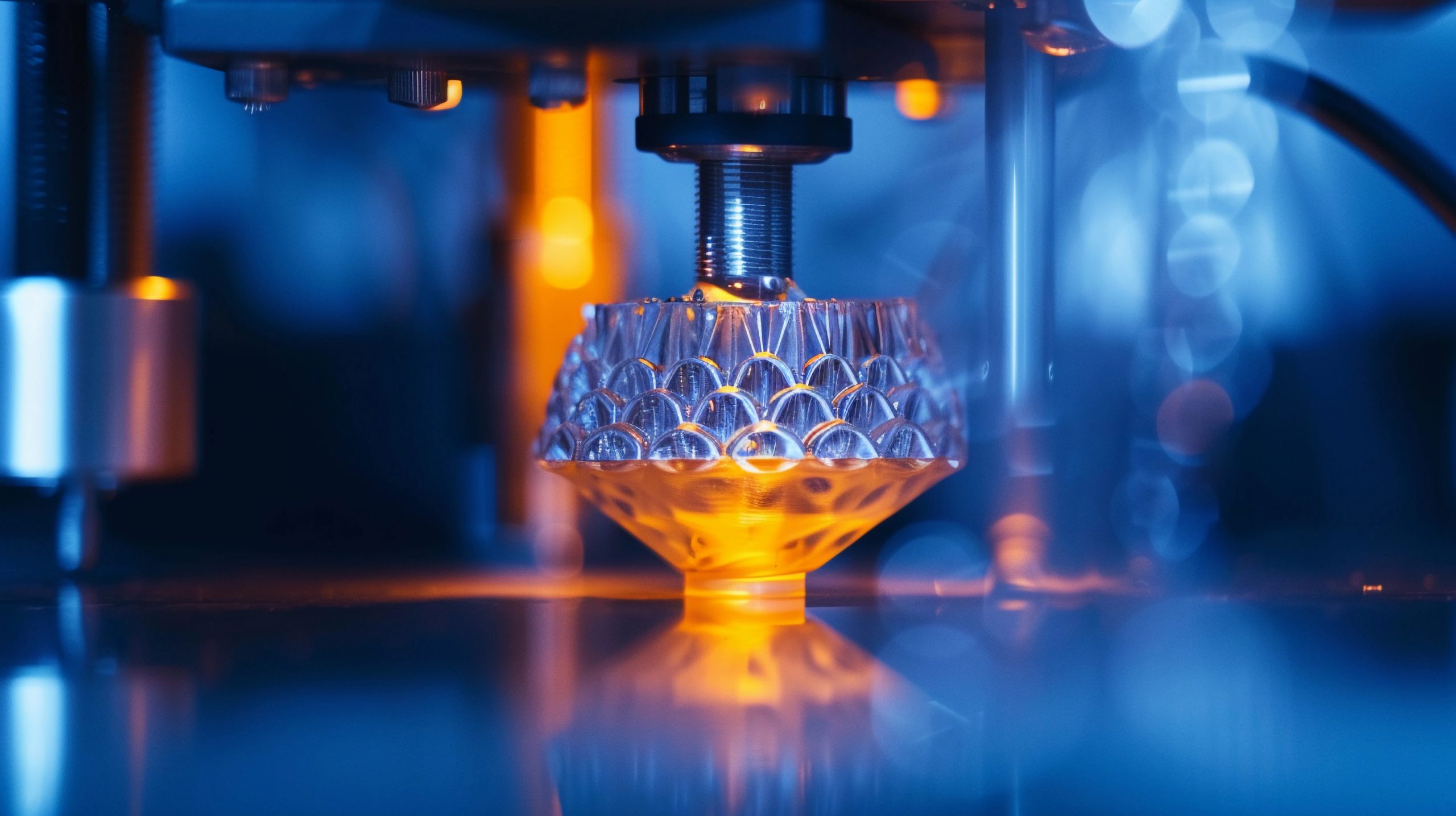

4. Preparation for 3D Printing

- Finalize 3D Model: Make final adjustments to meet functional and aesthetic requirements.

- Select Material & Print Settings: Choose materials and configure printing parameters (e.g., layer height, speed).

- Run Slicing Software: Convert the 3D model into G-code using slicing software for efficient printing.

5. 3D Printing & Quality Control

6. Testing & Iteration

- Conduct Functional Testing: Test the prototype for usability, durability, or fit if it’s intended for assembly.

- Gather Client Feedback: Share the prototype with the client for input and improvement suggestions.

- Revise Model as Needed: Adjust the model or settings based on feedback and reprint if necessary.

8. Delivery of Final Prototype

- Prepare Prototype for Delivery: Package the prototype securely, especially if it has delicate or intricate parts.

- Send Final Prototype to Client: Deliver the prototype via the agreed-upon method (in-person pickup, shipping, or delivery).

- Follow-Up with Client: Confirm receipt and satisfaction with the final prototype, addressing any additional questions.